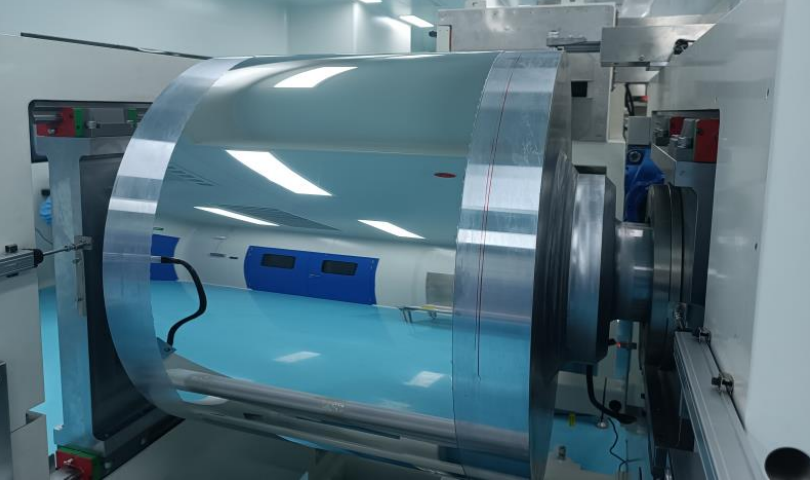

Coating a solution of thermoplastic or a prepolymer sol of thermosetting plastic onto a peelable steel belt, heating and drying it in a drying oven, and then melting and plasticizing it into a film layer. After cooling down, it is peeled off from the surface of the steel belt and rolled up to form a film.

The steel belt should be made of 301 stainless steel or 304 stainless steel, with good creep resistance, preferably 304 stainless steel belt. The roughness of the film contact surface should be mirror or 2B surface, with good flatness, no scratches on the surface, and good straightness.

Steel belt size deviation: Thickness tolerance range (+/-8%)

Width tolerance range (0-2mm), steel belt straightness deviation range (≤ 5mm)

Surface smoothness of steel belt: Ra ≤ 0.4 μ m

Surface flatness of steel belt: (flatness h: l ≤ 1:250, hmax ≤ 3mm)